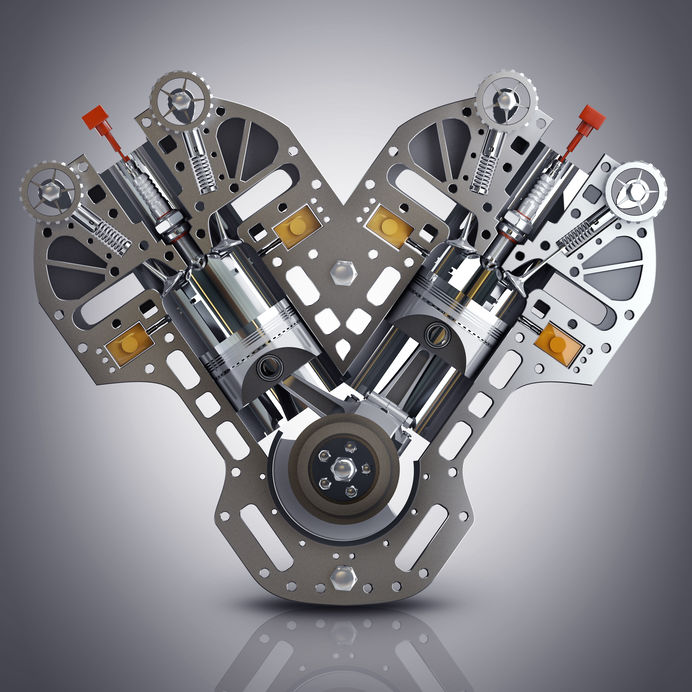

LS and SBC (Small Block Chevy) Engine Repair Service

A healthy engine is vital to your vehicle’s lifespan. Oil changes and replacing spark plugs are examples of common maintenance procedures but if your engine starts making new noises, this probably will require more than just an oil change or tuneup. Unusual engine noises, such as grinding, heavy knocking, or sounds of the engine struggling, you may need to repair it. We are here to help!

At MarvLs Engines we do not only build new LS and SBC engines, we also fix damaged or worn engines. Our engine repair service covers engine problems from simple to complex. The only exception to our repair services is if there is severe damage to the block (cracked block). In this case, we would simply recommend a new LS engine, either our Performance LS Engine Build or our Stock LS Engine Build.

Common problems we service are:

- Engine knocking

- Noisy lifters

- Worn engine bearings

- Piston Slap

- Damaged rockers

- Damaged engine gasket/seals

These problems usually occur on high mileage engines and are fairly simple to repair. We can also convert a used LS or SBC engine into a high performance engine. Whatever your budget allows and heart desires is the only question! This is a more affordable option than buying a new mild or high performance engine and does NOT require a core charge. (A core charge happens when an engine block is not provided).

Bottom line… We want to save you money and get you the engine you desire. Lets discuss your project and affordable options today! If you have any questions regarding our engine repair services, please Contact Us anytime.